Right side (22.5 hrs)

In this post I am going to complete the longeron repairs by finishing the right one. I’ll mostly dump the photos here and add some comments. For a more thorough explanation of what and why, check out the left longeron repair.

|

| Broken longeron with 3D printed ABS cutting guide nailed to it |

|

| Longeron getting cut along the 7:1 cutting jig |

|

| A top view of the surgery |

|

| Removing the damaged longeron from the fuselage |

|

| What it looked like right after the two sawing operations |

|

| All cleaned up and ready to get worked on |

|

| This fiberglass corner got damaged during the fall, and will need to be replaced. |

|

| I started by floxing the part where the foam got removed. I reused the jig to contain the flox. |

|

| After a little sanding, I had a flat base for the next operation. |

|

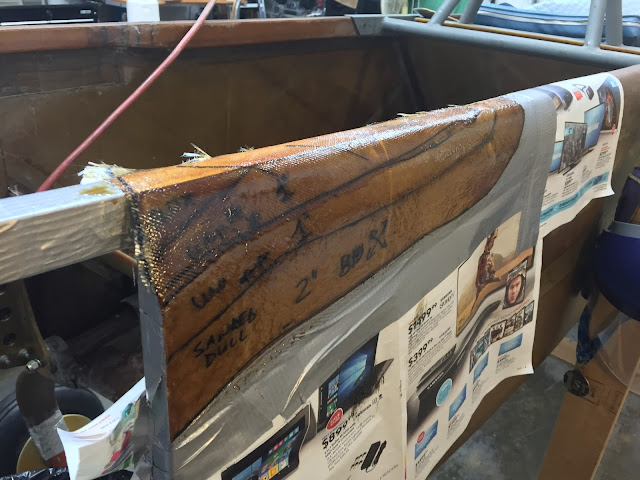

| The 3D printed ABS jig was used again (on a table) to cut this longeron splice |

|

| 2 BID plies at 45º replace the original substrate. Most of this will be eventually cut off to accommodate the CS spar. |

|

| Right after peel-ply removal, the next day. |

|

| BID trimmed down to size |

|

| Getting ready for the longeron splice installation |

|

| Once again, flox only was used as a bonding agent. |

|

| Flox added to both sides of the splice, and the sidewall. |

|

| Careful longeron alignment |

|

| Pressure added during the cure |

|

| Laying out a plan for the outer fiberglass replacement |

|

| Original fiberglass sanded in accordance with the plans' repair section (page 3-22) |

|

| First layer of UNI being laid |

|

| UNI saturated with epoxy |

|

| Second layer of UNI laid with opposite orientation (as per plans) |

|

| Second layer wetted with pure epoxy |

|

| Additional BID layer to cover the repair |

|

| With the surgery completed, this patient needs some rest time to be fully cured. |

|

| Peel-ply bandages, and Saran wrap to keep air from infiltrating. |

|

| Finished outer repair |

|

| Prepping for the "inside job" |

|

| BID pre-preg ready to be impregnated |

|

| Epoxy mixed with Cab-o-Sil painted over longeron and sidewall. A flox fillet was added in the bottom corner. |

|

| Pre-preg applied to the fuselage. All air bubbles were later squeegeed out. |

|

| Inner repair after the addition of peel-ply |

|

| Peel-ply removed the next day |

|

| This longeron repair is done! |

Welcome back! You are now in good standing with the canard building community once again! ;)

ReplyDeleteGood looking work Marco!

ReplyDelete