Getting in, and especially out of a LongEZ’s back seat can be a bit tricky.

With the nose down (grazing position) the passenger steps over the fuselage with the left foot onto the pilot’s seat, then swings the right leg over the strake and into the rear compartment (preferably not on the seat cushion).

As one does this, there is a strong need to grab something to steady oneself and not fall backward onto the Tarmac. Lack of directions in this procedure might cause an inexperienced passenger to fall off the plane, bringing with him parts of the structure he shouldn’t have touched, let alone grabbed.

There is only one structure between the seats that is sturdy enough to withstand any force, the headrest. Unfortunately, that is not evident when standing tall between compartments.

|

Terry and me at Rough River 2016

|

A metal rollover structure would be an ideal place to grab, but JT doesn’t have one, so I decided on the next best thing… a dedicated passenger handle attached to the headrest.

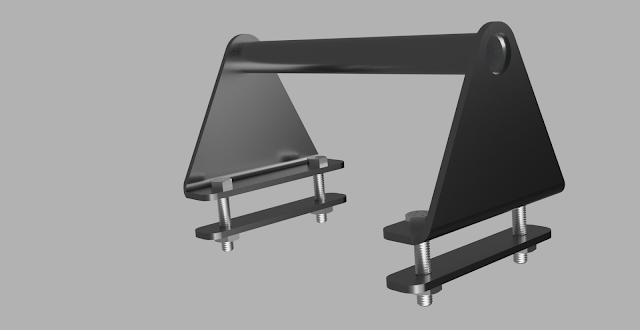

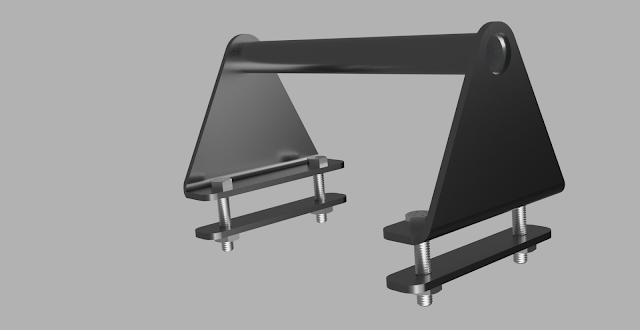

I designed it in CAD, then cut the basic parts on the plasma cutter for later bending and welding.

|

CAD helps get idea out of one's head

|

Not having a bending brake handy, I had to rig something up in the press so that I could make the same bend on both sides.

|

Using thickness gauges to repeatably position the bending extrusion onto the part

|

The setup was a bit ghetto, but it worked flawlessly producing two identical parts.

|

Not great for a large production run, but good enough to bend two parts.

|

|

You can see how the extrusion created the large radius bend

|

|

Another look at it

|

|

Symmetry is what I was after

|

Next, I jigged all the pieces up on the table, and did a pretty ugly but sturdy welding job on them. This was only my second time welding aluminum, and it showed. However, after a bit of grinding it looked passable.

|

Best chance to make a part as designed is to make sure nothing is able to move.

|

|

Well, it's not pretty, but it's strong and doesn't wobble.

|

|

Definitely overbuilt, even after grinding the welds.

|

|

Looking good enough to be pressed into service

|

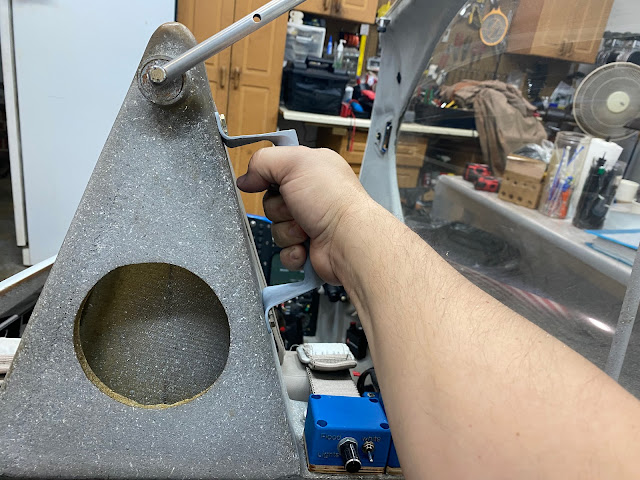

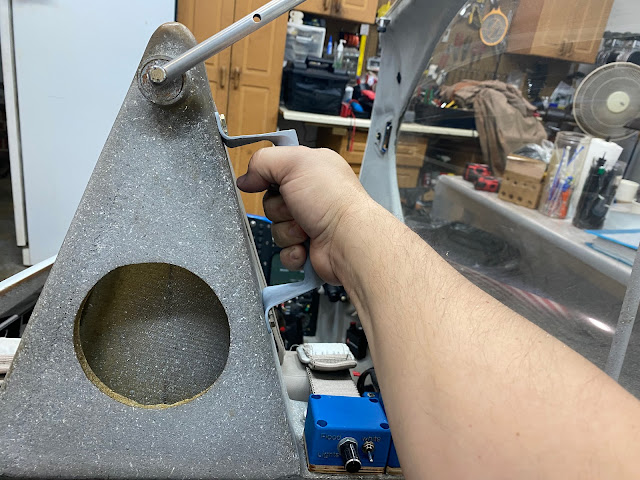

After a coat of primer I installed it on the headrest using backing plates on the inside.

|

I think it'll work

|

|

I'm liking the fit so far

|

|

Backing plates add a ton of sturdiness to this design

|

It is hard to believe how sturdy this handle turned out to be, one can literally pull himself up from the back seat without trouble. Every passenger seems to appreciate this unexpected secondary use of it.

|

Doesn't impede passenger's forward vision that much

|

|

Wow, this thing is sturdy as hell! I can even pick my not-so-light self up from here.

|

Getting in and out meanwhile has been easier than ever.

|

Perfect place to grab and steady oneself

|

The biggest drawback is that it’s a bit hard to spot in the gray color.

|

Very inconspicuous (perhaps too much), but oh so helpful.

|

I shall add some color to make it stand out soon.

Bravissimo

ReplyDeleteNice job buddy.

ReplyDelete