Fixture plate

There are many ways to hold on to stock material for machining.

Up until now, I have been using typical devices such as vise, clamping kit, or adjustable clamps. They all have their pros and cons.

|

| Stock held in the vise |

|

| Extremely versatile clamping kit |

|

| Adjustable clamp |

The vise has always been my go-to device. It’s easy to use, but it is also limiting in many ways. It needs to be aligned with a dial indicator every time it is mounted, it raises the stock thus limiting Z axis effective travel, it leaves longer stock overhanging and unsupported (as in the first photograph), it is generally not very repeatable, and the parts held are not always completely leveled without the aid of a dial indicator.

The clamping kit is a lot more versatile than the vise, but has most of the previous drawbacks, on top of being more difficult to setup. If that wasn’t bad enough, the clamping kit is so big that it consumes half the space on the milling table.

The adjustable clamps are pretty cool. Compared to the clamping kit, they are easier and quicker to use, and while they are smaller, they still take up a lot of real estate on the mini-mill small table.

Milling has thus far been a somewhat frustrating experience, mostly due to the difficulties involved with set up. It is not uncommon to spend more time coming up with creative ways to hold on tho the raw material than actually machining it.

A better way to go about it, is using a fixture plate.

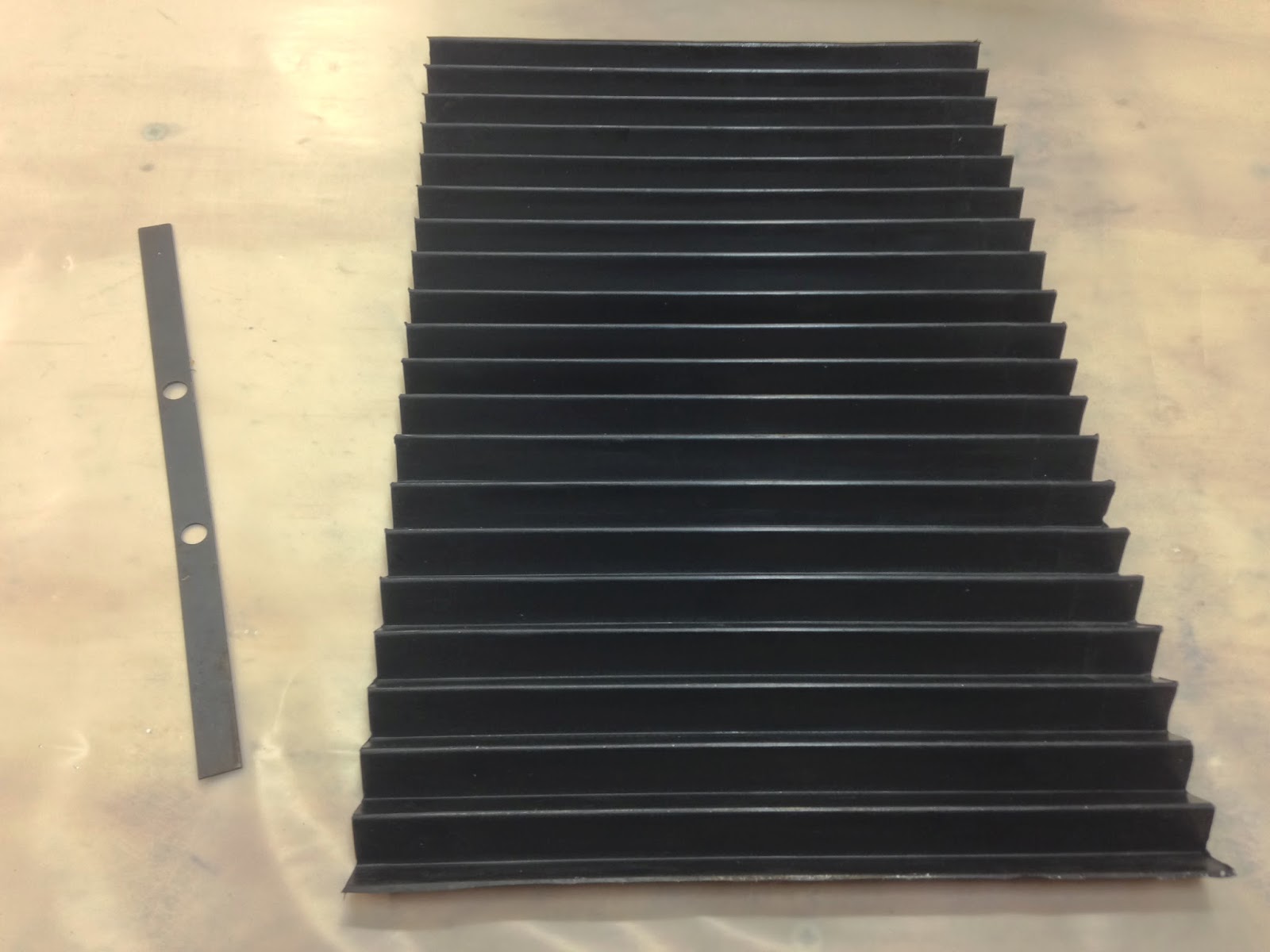

|

| Fixture plate |

A fixture plate (also called a tooling plate) makes it easy to quickly mount things and be assured of perfect alignment. A fixture plate is a metal plate, clamped to the mill table, with many precision spaced holes, some threaded, and some for dowel pins. With it you can precisely bolt parts, vises, and other accessories to the table, and they'll be right the first time/every time.

With very high expectations, I decided to purchase one online…

|

| Purchased from deepgroove1.com |

… and mounted it on the the table.

|

| The fixture plate did not come with T-nuts, so I had to make my own. |

To create a visual representation of the surface area I can machine, I placed a permanent marker in the spindle, and marked the fixture plate with the outline of the effective travel of the mill. In other words, everything falling inside the black rectangle can be reached by the spindle, and machined, and after the last few improvements I made to increase the X and Y travel, this area has grown quite large.

|

| Scope of the mill outlined in black |

I mounted the two straight bars that came in the kit parallel to the X and Y axes, so that I will be able to shove parts in the corner, and lock them up with the supplied cylindrical clamps. These clamps are pressed against the part by the action of eccentric bolts.

|

| Eccentric bolt vs standard |

|

| Eccentric bolt in the clamp |

|

| Stop bars and clamps setup for brake bracket |

This method of clamping is very fast, and very repeatable. I practiced clamping on and off an odd shaped object, the brake bracket, and it worked beautifully.

|

| Bracket clamped securily |

|

| Note the different size clamps |

|

| Bracket can now be removed, and precisely replaced in seconds. |

How to use the fixture plate